Automatic old rubber pyrolysis plant

- Packaging:

- HC FR wooden boxes

- Productivity:

- 15ton

- Brand:

- Lanning

- Transportation:

- Ocean,Land

- Place of Origin:

- China

- Supply Ability:

- 300

- Certificate:

- ISO CE TUV BV SGS

- HS Code:

- 8419899090

- Port:

- Lianyungang Port,Qingdao Port,As Required

Basic Info

Model No.: LN-2800-8000

Product Description

Automatic Old rubber pyrolysis plant

Henan lanning Technology Co., Ltd is a professional manufacturer

specialized onAutomatic old rubber pyrolysis plant

locates in Henan province shangqiu city; mainly changes waste rubber/plastic/ tires into fuel oil ...

Fully Automatic Waste Tyre Pyrolysis Machine working process

Firstly, make reactor rotate clockwise 0.4r/min, put raw material into reactor, close feeding door.

Secondly, burned the fuel material(coal,or wood,or natural gas ,oil ) in the furnace. Reactor will be slowly heated, when the temperature reach around 180 oC, oil gas will come out .

then go to cooling system and liquid to oil.Some incondensable gas which can't cooling down will be lead to furnace through a gas pipe. It will be used to heat reactor.

This can save your energy. Only the first 2 hours use energy for heating. After the first 2 hours mainly use gas, little energy is ok. After pyrolysis, all the oil gas come out from reactor, the temperature will fall down. Then make it rotate anticlockwise, carbon black discharging begin.

Lastly,when the temperature deduce to 50 oC, worker can opened the door of reactor take steel wire out.

Warranty on envionmental pyrolysis machines

We guarantee the complete machine one year since installation. If during the first year, there is any problem caused by the machine quality, we take responsibility. And we guarantee the reactor life more than 4 years, others parts no need to change. We provide the whole life maintenance for the machine

The function of the final products from Latest Rubber Pyrolysis Machine:

Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or

chemical industries or hotels, restaurants etc. or used for generators to get electricity.

Carbon black: used for construction bricks with clay

also can be used as fuel

Combustible gas: Can be recycled and used during process as fuel.

Construction bricks with clay

also can be used as fuel

Combustible gas: Can be recycled and used during process as fuel.

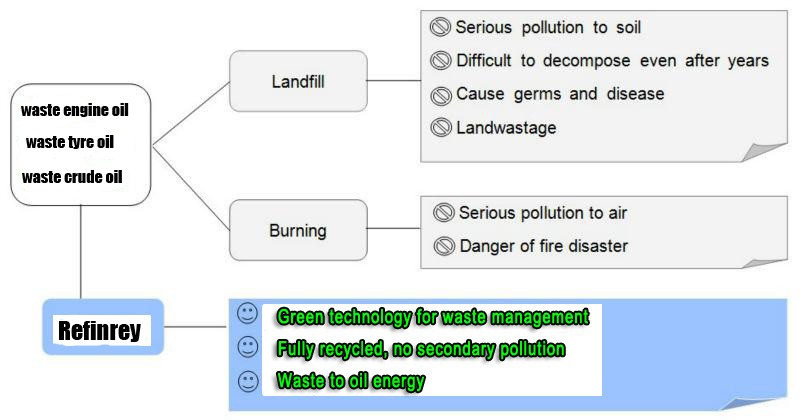

waste processing ways:

offices overview:

manufacturing process details of Fully Automatic Waste Tyre Pyrolysis Machine:

customer visiting on Latest Tyre Pyrolysis Machines:

delivery of Latest Tyre Pyrolysis Machines:

onsite installation:

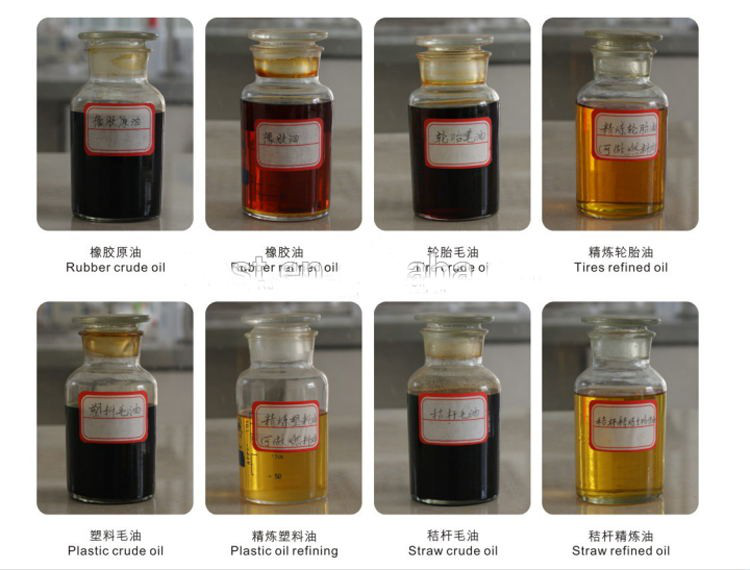

final oils:

certificates:

please contact us for more information!

Product Categories : Tyre Pyrolysis Machine Auxiliary > Double-side Tyre Cutter